Are Industrial Knife Carts with Drawer Locks Slowing CNC Production?Speed Boost Tactics

CNC machining relies on precision and speed. Every second counts in a competitive manufacturing environment. But are your tools, stored on industrial knife carts, contributing to delays? Specifically, could the drawer locks on these carts be slowing down your CNC production? This might seem like a minor detail. However, in high-speed manufacturing, minor friction points can become major bottlenecks. Let’s explore this potential issue and discuss practical speed boost tactics.

The Hidden Cost of Access Time

Think about your CNC workflow. A machine stops. An operator needs a specific cutting tool or knife. They walk over to the industrial knife cart. They try to open a drawer. It’s locked. They fumble for the key. Or, perhaps, they need to press a release button, which might be awkwardly positioned. This takes time. Even a few seconds per tool change adds up. In a busy shop floor, these seconds multiply quickly. Delays like this impact overall production speed. They disrupt workflow. They can even lead to increased manufacturing downtime if a tool is urgently needed.

Industrial knife carts are essential for organizing tools. They keep sharp items secure and out of the way. Drawer locks serve a purpose. They prevent unauthorized access. They keep tools secure during transport. But, are they always the most efficient solution? Consider the nature of CNC production. Operators need quick, reliable access to tools. Anything that adds steps or potential delays can be detrimental. Traditional key locks are notoriously slow. Losing a key is a major headache. Push-button or combination locks can be faster. Still, they require an extra action. This action interrupts the smooth flow of work.

Could these seemingly small delays be costing your CNC production? The answer often depends on the specific workflow and the type of locks used. If operators spend noticeable time unlocking drawers, the impact is real. It’s not just about the time itself. It’s also about the frustration and potential errors that can arise from rushed actions. A smoother workflow contributes to better focus and fewer mistakes. This is where speed boost tactics become crucial.

Speed Boost Tactic 1: Evaluate and Upgrade Lock Mechanisms

The first step is to assess the current situation. Observe how operators interact with the industrial knife carts. Do they struggle with the locks? Do they complain about access time? Be honest about the impact. If drawer locks are indeed a bottleneck, consider upgrading the mechanisms. Look for locks designed for speed and ease of use.

Some modern drawer locks use simple, intuitive mechanisms. For example, a push-to-open or pull-to-release design eliminates the need for keys or complex codes. Magnetic locks can offer secure closure without any physical unlocking step required by the user. These types of locks can significantly reduce the time needed to access tools. They integrate more seamlessly into the fast-paced CNC workflow. The goal is to minimize the steps between needing a tool and having it in hand. Investing in faster lock mechanisms is often a quick return on investment. It directly translates to faster production cycles.

Speed Boost Tactic 2: Optimize Cart Layout and Organization

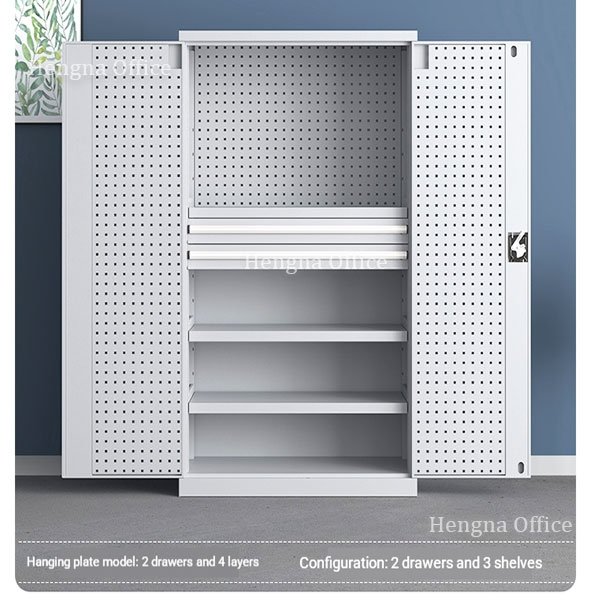

Drawer locks are just one piece of the puzzle. The overall layout and organization of the industrial knife cart matter too. A well-organized cart allows operators to find tools quickly. This reduces the time spent searching, even before considering the lock. Use clear labeling. Label each drawer or section clearly. Indicate the type of tools stored inside. Consider using color-coded dividers or trays within drawers. This makes it easier to visually locate the needed item.

Group tools logically. Store similar tools together. Keep frequently used tools in the most accessible drawers, often the top ones. Ensure that the drawer locks themselves don’t interfere with this logic. For instance, if a drawer with high-use tools requires a unique key or a specific button sequence, it defeats the purpose of easy access. Align the organization strategy with the speed of the lock mechanisms. A combination of fast locks and logical organization creates an optimal environment for quick tool retrieval. This directly supports faster CNC production.

Speed Boost Tactic 3: Implement Quick-Release Drawer Systems

For the ultimate speed boost, consider industrial knife carts featuring quick-release drawer systems. These systems often eliminate traditional locks entirely. Instead, drawers might slide out fully on smooth-gliding tracks. A simple pull or lift mechanism releases the drawer from its housing. Some designs even allow drawers to be removed completely for tool changes far from the cart. This provides unparalleled access speed.

Quick-release systems remove the friction point entirely. There are no keys to find. No buttons to press. Operators can grab the tool and return to the CNC machine almost instantly. While these systems might represent a higher initial investment than carts with standard locks, the productivity gains can be substantial. They are particularly valuable in high-volume production environments where every second of machine uptime is critical. Evaluate if the benefits of near-instantaneous tool access justify the cost difference for your specific CNC production needs.

Speed Boost Tactic 4: Integrate Cart Placement into Workflow Design

The physical placement of industrial knife carts on the shop floor plays a role in overall speed. Carts should be located strategically. Place them close to the CNC machines that use the tools they contain. Minimize the distance operators need to travel. This reduces walking time, which is another form of production delay.

Consider the flow of people and materials. Ensure carts are placed in areas that don’t create traffic bottlenecks. Good visibility is also important. Operators should be able to quickly locate the cart they need. Integrate the placement of industrial knife carts as a deliberate part of overall workflow design. This holistic approach ensures that the carts support, rather than hinder, the smooth operation of CNC production. Even the fastest lock or most organized drawer is less effective if the cart itself is poorly positioned.

Speed Boost Tactic 5: Regular Maintenance and Staff Training

Finally, don’t overlook the importance of maintenance and training. Ensure that all drawer locks, regardless of type, are functioning smoothly. A sticky lock or a jammed drawer can cause unexpected delays. Regularly inspect and maintain the industrial knife carts. This includes checking tracks, hinges, and locking mechanisms.

Train staff on the correct and efficient use of the carts and their locking systems. Make sure they understand the organization system. Empower them to report any issues promptly. Well-maintained equipment and well-trained staff are fundamental to achieving optimal speed and efficiency. These elements work in concert with the physical design of the carts and their lock mechanisms.

Conclusion: Reclaim Lost Time on the Shop Floor

Are industrial knife carts with drawer locks slowing your CNC production? The answer is often yes, at least to some degree. Even seemingly minor delays in tool access can accumulate, impacting overall production speed and efficiency. By implementing targeted speed boost tactics, you can mitigate these delays.

Evaluate your current lock mechanisms. Upgrade to faster, more intuitive options if needed. Optimize the layout and organization of your industrial knife carts. Consider the benefits of quick-release drawer systems for maximum speed. Strategically place carts within the workflow. Ensure regular maintenance and staff training. Each of these steps contributes to a smoother, faster CNC production process.

Don’t let outdated or inefficient tool storage solutions be a hidden cost on your shop floor. Analyze your current setup. Identify the friction points. Implement the speed boost tactics discussed here. You may be surprised at how much time and productivity you can reclaim. A focus on efficient tool access is a direct investment in the speed and profitability of your CNC operations. Upgrade your approach to tool storage. Experience the difference it makes.